Engagement Ring - In Progress

Setting

Stone

Limited Time! Purchase any Engagement Ring and Receive a $250 Gift Card & Premier VIP Bundle.

We guarantee that every single purchase directly impacts one person's life by giving them access to clean water.

As the founder of Do Amore, I want to share with you the genuine reasons behind our shipping times and why it is usually 2-3 days longer than other online jewelers.

First off, I wish this wasn’t the case. It means we miss out on sales from customers who have an urgent timeline, and since we really want to be the best of the best, I wish the best could include the fastest production time too. As a mechanical engineer myself, efficiency and optimum production are extremely important to me – but with fine jewelry, timing does affect quality and it’s just something we decided early on that we aren’t okay giving up on. I thought it would be interesting to share the process and where those extra few days get added in, and why:

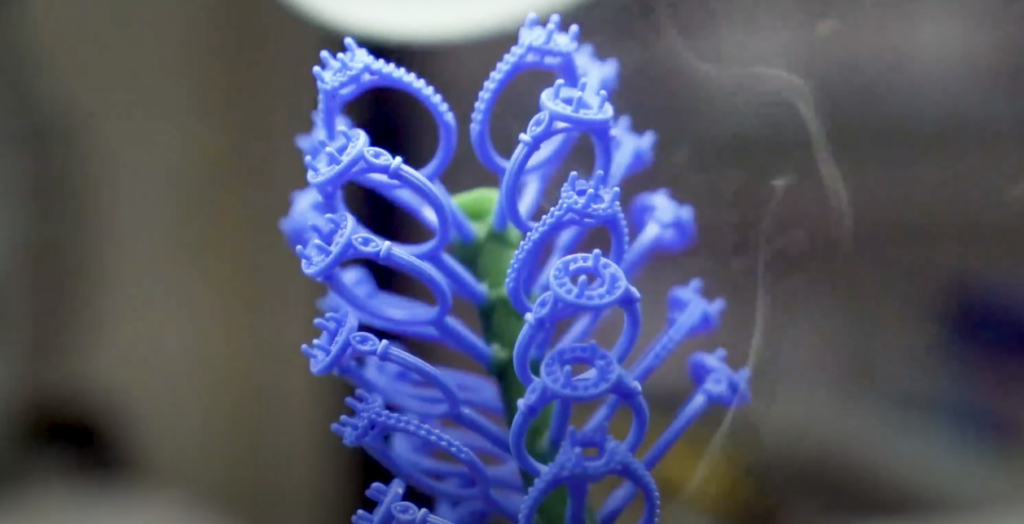

Every single ring we create is made-to-order because we want every piece we create to be handcrafted specifically for your ring size and your center stone size. For this reason, when an order comes in, we actually make a new wax to your exact ring size and to your exact stone dimensions. Oftentimes, this involves using a scanner that physically scans your diamond in 3D, capturing every detail of your diamond, which then allows us to tailor the prongs and basket of your ring to create the perfect precise fit for your diamond.

This process adds 2 days right off the back.

We no longer lose time during our casting process relative to others. Because of our commitment to using recycled precious metals, we used to lose about 2 days here as we had to send in the recycled gold casting grain for each order. However, now we have enough volume that our manufacturing team keeps an inventory of recycled gold casting grain and we do not lose any time.

We do not lose time during our pre-polishing process relative to others

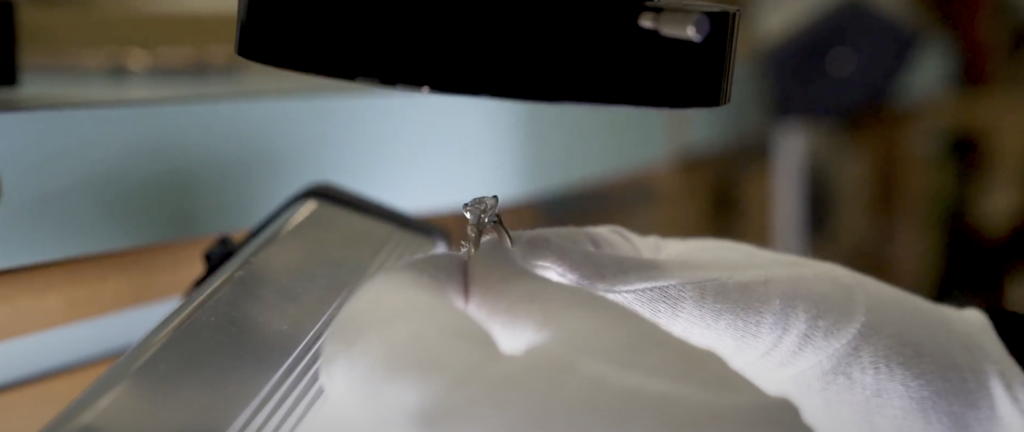

Our setters use a microscope to set both the centerstone and the smaller side diamonds. This process allows them to be more detailed and helps them position each prong over each diamond properly and perfectly. There are two advantages we have found in doing this process, which definitely takes more time: First off, it allows us to make sure that each side diamond prong is positioned in an ideal manner to allow for maximum light to enter and exit each stone (which creates sparkle), and it helps to ensure stones are set in the sturdiest manner possible.

After the diamonds and gemstones are set, our jewelry undergoes a final polishing process. This step is carried out by hand, ensuring that every inch of the jewelry is perfectly smooth, comfortable, and free of imperfections. While all jewelry undergoes polishing, we give polishing about a ½ day leeway so that they can take more time and ensure they are doing everything a bit slower. The biggest advantage of doing slower is that it helps to prevent something called “overpolishing”, where a ring is polished too much thereby creating weak points in the ring, and asymmetry.

Quality control is an essential aspect of our process at Do Amore. Our team inspects each piece, making sure it meets our high standards for quality and craftsmanship. If any issues are found, the piece is attended to even if it means remaking the ring again. This level of care ensures that every piece of jewelry leaving our workshop is of the highest quality and that our customers receive a product they can treasure for a lifetime.

By handcrafting everything right here in the USA, we are saving about 1-1.5 days on every ring because we do not have to wait for shipments to arrive from overseas daily, and clear customs. Doing everything here in the USA has several advantages, and timing is for sure one of them.

While I wish we could reduce the time further for our customers, I believe we are currently at the optimum production time and do not think it is possible to go faster without sacrificing quality. The good news for us is that generally, proposals are planned ahead, and taking 2-3 days longer than our competitors does not affect the large majority of our customers. We believe that the end result is a unique, timeless, and elegant piece of jewelry that you can feel proud to wear for a lifetime. While the wait may be a little longer, we hope that you understand and appreciate the care and dedication that goes into creating each piece.

Thanks for allowing me to explain the process and I hope you all found it somewhat interesting.

Verifiably Ethical & Sustainable

Guaranteed 1:1 Impact

Personalized 1:1 Customer Service

handcrafted & american-made

you before us, always

Verifiably Ethical & Sustainable

Guaranteed 1:1 Impact

Personalized 1:1 Customer Service

handcrafted & american-made

you before us, always

Thoughtfully crafted, made to last, and designed for life's most meaningful moments. LEARN MORE

Diamonds, Gemstones, & Metals

Every piece of Do Amore jewelry begins by not hurting the world. All our natural diamonds are either ethically sourced in Canada, recycled to eliminate additional demand, or accompanied by a blockchain ledger showing every hand your diamond passed through, proving your stone is truly conflict-free.

We also offer sustainable lab-created stones and guarantee all precious metals are recycled to eliminate the environmental impact of mining. Since March 2022, we carry absolutely no Russian diamonds and continue to urge the industry to follow suit.

Clean Water

We desire to deepen the well of love in the world. We guarantee that every single purchase—whether engagement ring, wedding band, or piece of jewelry—directly impacts one person’s life by giving them access to clean water.

We do this by directly matching jewelry purchases to people in communities to ensure our funding has a one-to-one impact. We also show you the exact GPS coordinates and a photo of the water well your ring or piece of jewelry helped fund.

Customer Service

As a small, 100% founder- and employee-owned team, one-to-one encounters are at the heart of our values. Whichever way you want support throughout your engagement ring or jewelry purchase process, our team is here to accommodate you.

From high-touch to hands-off, video calls to text messages, you have our dedicated, responsive team on your side from the moment you start your search, to the day your well is built, to the time we meet again.

Engagement Rings, Bands, & Jewelry

Every Do Amore design, whether one of our own or unique to you, is beautifully handcrafted in America and made specifically for you. Each ring is made to order, every time.

From classic to custom, you have the option to select from dozens of gorgeous settings or work with our design team to create something entirely bespoke. Plus, you are always covered for free inspections, polishing, cleaning, stone tightening, rhodium-plating, and resizing for life.

Our Promise

We care about what matters most to you, not what’s easiest for us. If it’s a minor change to a setting or arriving at a completely custom design, we work to ensure you get precisely what you love.

From statement-making to understated, we have options at any price point. Plus, you always have our team on your side searching to bring you every stone within your specifications. We also offer 60-day returns and a limited lifetime warranty to cover you in the rare event of a manufacturing defect.